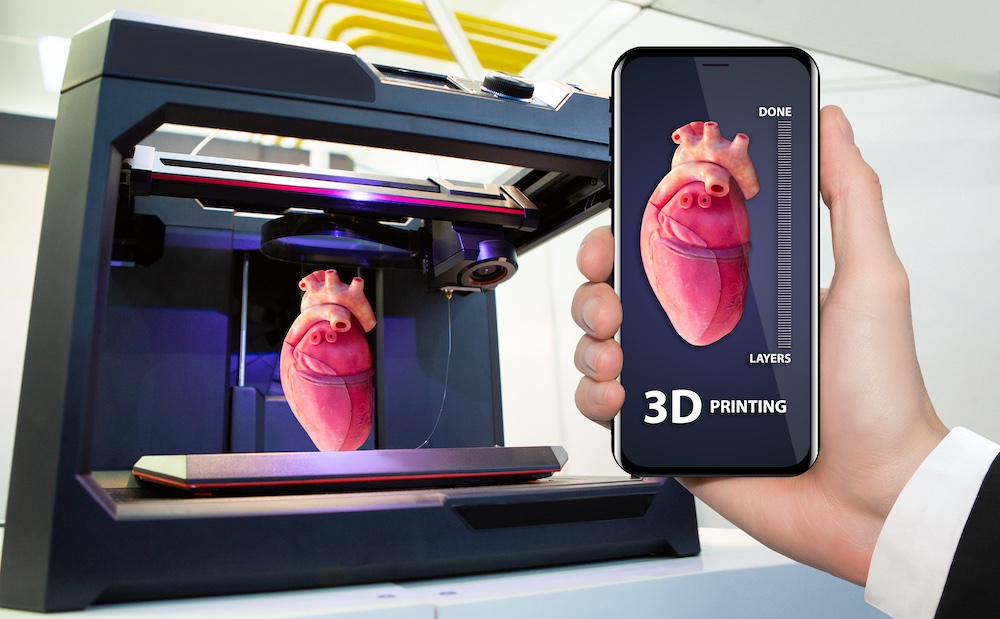

3D printing is one way the healthcare simulation community ventures towards innovation. Creativity and innovation are demonstrated at numerous healthcare simulation focused conferences’ showroom floors crowded with the latest upgraded task trainers and manikins. Many healthcare simulation centers throughout the world seek out new ideas and designs independently, to make medical simulation training better. One technology has the potential to dramatically aid any simulation center or amateur simulation maker in bringing an idea to life, 3D printing. This HealthySimulation.com article by Kirk Atkinson, a Simulation Operations Specialist at UT Southwestern, discusses 3D printing (Additive Manufacturing) and some questions any healthcare simulation program should ask when considering taking on the 3D printing endeavor.

The Short History of 3D Printing in Healthcare Simulation

In a look at the industry as a whole, the history of 3D printing in healthcare simulation is fairly young, with a few outlying simulation programs and simulation pioneers that bought into the idea very early. In a general discussion about 3D printing with the average simulation technician, the conversation will generally center around the topic of molds or 3-dimensional anatomy print outs. The limited use of 3D printing is where the conversation and the healthcare simulation community’s interest usually ends. However, if the early innovative adopters are examined in greater detail, a whole world of already realized possibilities for the use of 3D printing awaits.

The number of ambitious programs and motivated individuals that have and are utilizing 3D printing to achieve many amazing feats is on the rise. Without naming programs or individuals specifically, upgrades for specific medical simulation equipment, such as manikins and task trainers, have been created. Many programs employ 3D printers to print out customized pieces for task trainer upgrade and/or creation. The list for the capabilities of a healthcare simulation program that employs additive manufacturing, even on a small scale, is a long one with only the only limitation is the imagination and creativity of the user.

The Questions to ask about 3D Printing

For medical simulation programs and advocates looking to get into the wide world of 3D printing, there should be some questions asked as with any important decision. The majority of the questions could be traced back to one central question – “why”. Why is a healthcare simulation program, educator, doctor, nurse, or specialist interested in 3D printing? This question can take many forms and should be asked in many ways to determine if 3D printing is just a bright and shiny novelty item or something that will be used to help transform a medical simulation’s potential for the better.

Another important and transparent question to ask in regards to 3D printing is, “Will this 3D printer be used regularly for the simulation program’s benefit or is this a short-term use item?”. As with any new purchase deliberation from a business standpoint should be considered. Varied perceptions should be sought to identify when 3D printing could and should be used and if it would be used regularly for some task or training that will bring benefit to specific people or groups of people. A 3D printer alone and not printing, from a superficial glance, definitely has the potential to give any onlooker the impression of an unnecessary expensive paperweight. On the other hand, a 3D printer that is utilized and surrounded by successful prints and prototypes will pass the hard scrutiny of worth from skeptics. The question of whether this 3D printer is a benefit or a shiny new toy, is a question that should be answered truthfully.

As a stem from the root question of why, any substantial purchase will always be met with the question, “What will this be used for?.” Utilization is one of the most appropriate questions to determine before a head first dive into 3D printing. To help justify a 3D printer’s purchase, a comprehensive list of uses for the 3D printer should be assembled. The question of use and viability should be asked to anyone who could potentially benefit from this manufacturing capability. Even off-the-wall fantastical (but still medically relevant) requests should be added to the list.

The allure of 3D printing is very attractive due to the strategic advertising of what can be created from seemingly nothing. The idea of creation is most aptly true for not only 3D printing but also the entirety of healthcare simulation, when looked upon from an outsider’s perspective. However, just as with healthcare simulation, with 3D printing there is an unseen process that makes the magic happen. In additive manufacturing, those processes are computer aided (assisted) design, printer preparation, slicing software calibration, and post process; not to get too in depth.

Another question that arises from the full 3D print process is, “If someone is not already well versed in 3D printing and Computer Aided Design, is someone in the center willing to devote time to learning all that is required for 3D printing?”. If someone in the medical simulation program is familiar with these processes, that is a large positive, but reality will probably not be that kind.

The Realistic Understanding of 3D Printing

In a needs assessment where questions about the potential of 3D printing are asked, one viewpoint may become apparent that will need to be addressed. That viewpoint will most likely be that the population at large has a very polished and high idea of what 3D printing really is. The unfortunate reality is that the mass-conceived idea is not the bulk of 3D printing/additive manufacturing, but a small and expensive fraction. The most affordable and accessible 3D printers are Fused Filament Fabrication (FFF) or Stereolithography (SLA) printers. These 3D printers, while very capable in the trained hands, can only deliver so much detail and color, which may fall short of some expectations. The explanation of this reality is meant not to dissuade but to inform. FFF and SLA printers can still deliver remarkable 3D prints and can give a healthcare simulation program amazing manufacturing capabilities.

3D printing, with the already established history, has a place in and might be the way of the future in healthcare simulation. For any medical simulation program looking to dive into 3D printing, a needs assessment is a must. A long and honest look at what are the simulation program’s needs, what expectations are, and what fits the budget.

A 3D printer is not a simulator, a task trainer, or a VR ambulance simulator and should not be assessed the same way as those technologies. Additive manufacturing is a burgeoning technology, relatively speaking to the recent popularity and availability/affordability on the market. Healthcare simulation centers can wade into the additive manufacturing pool slowly until comfortable enough to go deeper; all while still reaping the benefits. The world of 3D printing/additive manufacturing is a vast world with plenty of unrealized potential for any healthcare simulation program that has the will to take on the endeavor.